Water supply within a data center poses specific challenges for the installation of cooling water systems. Water cooling is in fact required due to the high discharge of thermal energy by state-of-the-art servers. Water-cooled server racks help to minimize the distance between cooling systems and servers.

CoolTherm®, the closed server rack featuring a water-cooled circulating air system, and CoolAdd®, the watercooled retrofit solution for a wide variety of current server racks produced by different manufacturers, function on the basis of a failure-proof connection with the cold water supply available in any building.

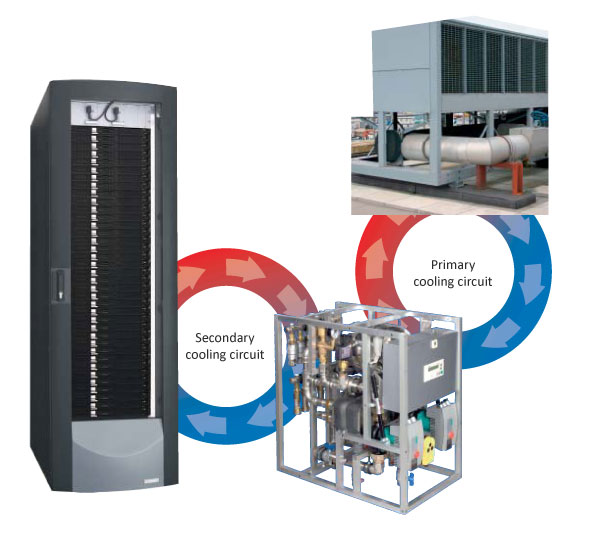

It is not however simply a matter of diverting the existing cold water supply into the data center.The Knürr CoolTrans® couples the building's main cold water circulation system with the data center's secondary cold water system by means of a water-towater heat exchanger.

The benefits are...

…the cold water flow temperature is controlled by the dew point temperature within the data center. In this way, any complex isolation of the data center’s water circulation system is overcome. At the same time, there will be no build-up of condensation whilst avoiding dehydration and the need to humidify the data center.

…since the secondary circulation system is operated above freezing point, use of glycol is no longer necessary. The coolers may be built to a smaller size, while maintaining the same level of performance, in order to avoid further investment.

…the water quantity within the data center is controlled by the secondary circulation system. Even the working pressure within the installation may be adjusted at a lower range than in the primary system. The recommended value is approx. 2,5 bar.

… temperature and pressure fluctuations within the primary circulation system are compensated for. The flow temperature can be controlled as a constant and adjustable value.

…the option of monitoring the secondary circulation system, including failure alarm management, protects constant operation and reports technical faults within the installation. Naturally, there is a spare back-up for all moving parts.

In addition, the relatively high flow temperature of 12°C and over allows for a high degree of free cooling in many climate zones, resulting in energy savings. In these cases, the system's capacity factor, i.e. the ratio between cooling performance and power consumption, increases drastically.

The Knürr CoolTrans® allows the mixture of cold water produced by free cooling with the main cold water supply.

CoolTrans® is available in the 50 and 100 kW power class. It indispensable for the safe operation of water-cooled racks by controlling the precise volume, optimum pressure and the required temperature.

Компания KNÜRR GmbH с 2016 года вошла в группу компаний Vertiv. С 2018 года завершен ребрендинг KNÜRR под общий логотип Vertiv, а наименование KNÜRR стало частью названий серий продукции.

Компания Vertiv занимается разработкой, созданием и обслуживанием критически важных технологий, предназначенных для центров обработки данных, коммуникационных сетей, а также для коммерческого и промышленного оборудования.